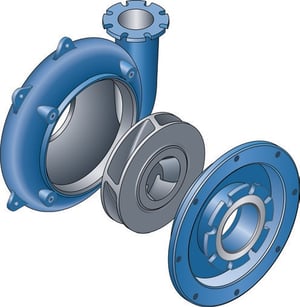

Since impellers are high-wearing slurry pump components, owners and operators need to maintain and remove impellers from their pump shafts when shaft sleeves or the impellers themselves require repairs or replacement. In fact, maintenance is of special importance as the impeller, along with pump casing and suction liner, determine pump performance. But what happens when a pump isn’t performing optimally due to a stuck impeller — and what could cause an impeller to get stuck in the first place?

Why is my impeller stuck?

Impellers can get stuck for many reasons. But pump owners and operators can avoid such issues by following this advice. Here are two scenarios GIW recommends against:

- Using only one gasket or none at all — GIW recommends using two gaskets. The gaskets work against one another for easier removal. When only one gasket is in use, the impeller will overtighten on the shaft, making it more difficult to get off. Therefore, using two gaskets is the best strategy. The two gaskets slide against one another, making it easier to break loose. If a gasket is not used at all everything will seize up.

- Applying anti-seize to the hub face — It seems practical to use anti-seize on the threads, faces of the shaft sleeve, the impeller, and the gaskets. However, anti-seize actually causes everything to overtighten. The reason for this is that anti-seize causes the parts to become more slippery and the parts will overtighten on the shaft. A good rule of thumb is to use anti-seize on the threads of the shaft and the impeller, but to keep the axial faces of the shaft sleeves, the gaskets, and the impeller hub dry. If anti-seize is applied to those areas, everything will tighten even further on the shaft and can over-torque and break pieces of the shaft or the impeller off itself.

In fact, most “stuck impeller” issues have to do with gaskets. But some extenuating circumstances exist that can also lead to impellers getting stuck on pump shafts.

Sometimes the threads break either on the shaft or the impeller, they get crossed, or the impeller won't break loose. Upon inspection, if the threads look damaged or broken, clean them up. A pencil grinder can be used to prevent more damage.

Putting a new impeller on worn threads can result in rapid failure and damage to other wet-end parts. Pumps with stuck impellers, will cause bearings to fail, which risk causing damage to pump motors. All of this can lead to additional repair issues. Once a bearing fails in the assembly, there is not much that can be done other than cutting the shaft off behind the impeller to remove it.

Safety tips

While a call to the pump experts for impeller assistance is always an option for such extreme cases, it’s not always a necessity. Pump owners and operators should follow these safety suggestions when troubleshooting if they have significant challenges removing their impellers.

If impellers aren't screwed all the way on when operators get ready to start up the pump, the impeller will slam against the shaft sleeve, and damage can be done to the impeller or the sleeve itself. Operators need to make sure it’s fully seated before starting up the pump.

Also, heat should never be applied to an impeller. The impeller rests in a sealed cavity and can explode. Because the impeller is part of the wet end of the pump, the moisture and air trapped inside pose a major safety danger. Pump owners and operators should avoid reversing the motor when an impeller gets stuck.

Following the proper impeller removal steps and using the safety tips featured above can prevent pump damage. When in doubt, simply call GIW for expert advice and assistance. And remember: Always put safety first!